First of all, thanks for all the experiences and solutions offered on this forum question. I wanted to follow up with which solutions that I have adopted.

1. Until such time as I get the rig into an observatory (which I desperately need), I will forego an extended dew shield. Such an addition offers a number of good reasons, even beyond the issue of dewing.

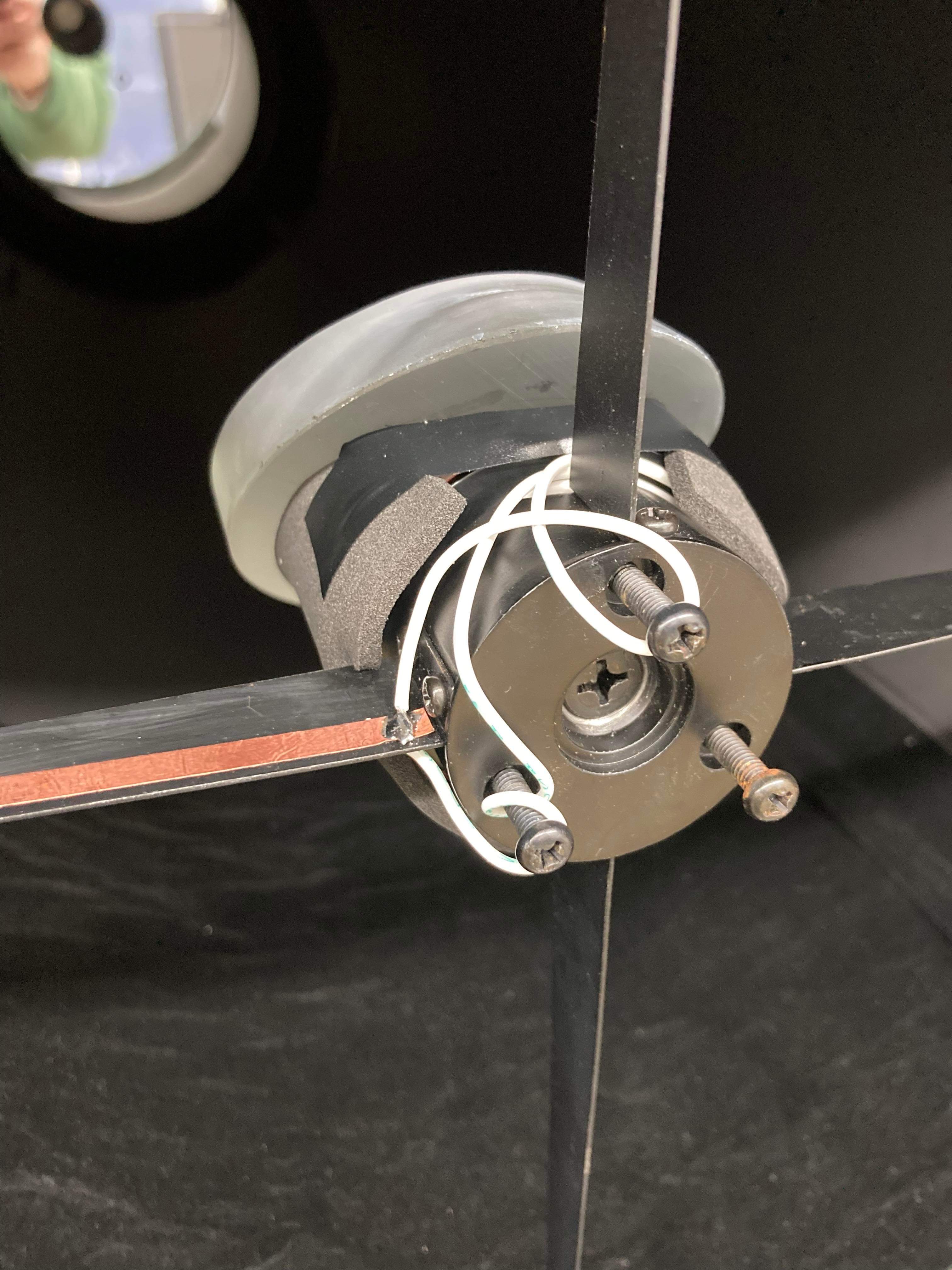

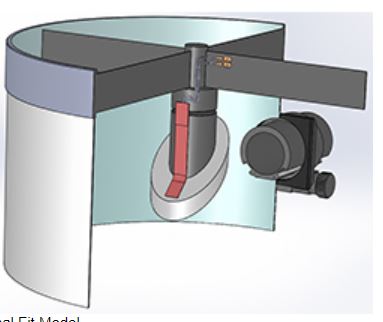

2. Secondary: Given the diy solutions found on CN and/or the commercial solutions, I have instead opted to use the heaters that I found on-line commercially, and at a very reduced price point. Starting with the secondary, I could not be sure that I could fit the Kendrick split ring item to my secondary. And there is no way I was going to pry off the secondary from its mount to put a full disk heater between the two. The strip heaters I could find on-line for a few bucks seemed not that different than the Kendrick model, so I went for the non-astro model. Here are some photos of the heater and the wiring via the spider using copper tape as suggested and shown above by

@Dale Penkala.

Note the strip heater runs down along the aluminum secondary mount and maybe just 1 cm onto the actual secondary. Most of the heat flows into the aluminum. The electrical connetions are via spade connectors. I need the ability to disconnect these so that I can change out the secondaries that I have for different imaging demands. The heater comes with an adhesive so the fabric tape is for light and insulation. I'll probably add a bit of tape to the other side of the secondary mount rib to balance heat flow and temperature across the full back of the secondary and mount. A bit of black "Shoe Goo" anchors the wiring near the connective end. Shoe Goo is extremely tough stuff.

You can see the copper strips used to connect to power. They are painted black. Very low profile (see next photo). A lot of copper tape is the 1 mil variety. Here, I found 3 mil tape, which I thought would be a better conductor and easier to solder. Tape is used to anchor, along with black Shoe Goo. Also, I added a barrel connector through the wall of the OTA. Yes I drilled my carbon tube! But I wanted a solid connection and in a location that did not interfere with the dust cap. Also, if I add a dew shield, I wanted the connection to be solid and in a consistent location. And no, none of the visible connections fall within the light path of this OTA, which itself offers a generous amount of space on the margins.

A not quite face on view, showing the low profile nature of the copper tape setup. My only concern is that the sellers of the copper tape claim that the adhesive is highly conductive. (I actually doubt that after testing with my meter.) So I was concerned that I might get a short between the two strips of tape and the metal in the spider. The black paint on the spider is sufficiently insulating. Lets hope is stays that way...

My concerns about the strip heater that I used is that its wattage is 10 watts at 12 V. This is a 3X more than the commercial strip heater I was looking at. However, upon use and setting the aggressiveness during use to a low setting, the heater works fine. Getting 4 heaters for $15 was also very very painless. Time will tell if these are durable. They are claimed to be sealed against the environment and indeed appear to be so. The resistive conductors appear to be thin foil, rather than NiChrome wire. It is quite flexible and can be closely pressed onto the changing surfaces of the secondary and mount. I actually used the other 3 strip heaters as temporary solutions on my primary (see below).

3. Primary heaters. Unlike the experiences mostly seen on this forum, my primary has been dewing up over the last month or so. So I have no choice but to heat my primary. Since my rig is open air, a fan seems illogical and I will not extend my scope until such time as it comes "indoors" with an observatory.

Because the heaters I planned to use for my primary were on a slow boat from China, I went ahead and temporarily mounted the remaining three strip headers that I got for the secondary to allow me to image for a few of the last clear nights here in Oregon.

For this, I did not want to remove the adhesive protective backing and just taped them directly on to the primary in symetrical locations. I also learned that using such heaters demands that they be wired in parallel. Doing so in series would effectively raise the resistance seen at the load and force the wattage output to extremely low max values. The heaters that I planned to use are now delivered and I will pull these strip heaters off and save them in case I need to use them for other projects. BTW, they worked spectacularly well at very low power draws from my PowerBox. Under very dewy conditions (every other surface ended up dripping wet), the primary stayed dry.

Here is one of the 4 heaters that I received this week. It cannot be seen in this photo, but the resistive conductor in this heater is clearly a wire, not a foil strip. I will assume it is NiChrome. This heater also is "sealed" in a much thicker silicone/fabric sandwich than the strip heaters. This heater is lower power than the strip heaters (7.5W spec, but likely under 7W as measured directly with the meter) and I plan on using 4 of these. 3 symetrically a few cm inside the perimeter of the primary and one directly in the center. I will attach these with a thin layer of silicone adhesive to ensure full coverage of the heater to primary. I will likely add a bit of silicone to the wire entries as I am not sure the there is a good seal into the wiring solder joints. This will provide 30 watts/hour of power, which happens to be roughly the power that the commercial heater for this size mirror offers. I would never expect to use more than a few watts/hour as I have learned from using the strip heaters. These heaters are relatively thick and the silicone adhesive will add a bit more thickness overall. I expect that this will slow and diffuse the heat transfer to the primary. That is fine. I hope not to have to cover these heaters with tape or other insulation for them to be effective. Either way, it has to be better than a peripheral heater wrapped around the edge of the primary. I do worry that if I need agressive heating, that uneven heating might cause a mirror surface artifact that might resemble pinched optics. But the expectations are that the heaters will not come on until very late in these sessions. I'll post a final photo of this setup.

Finally, I would like to stress that the total cost of materials, heaters, spade connectors, copper tape, and fabric tape amount to much less than the cost of a single small commercial astrophoto strip heater. Some of this, the copper tape, fabric tape and spade connectors, I would have bought regardless of which heater I went with. I do acknowledge that I am accepting a significant level of risk by using these cheap heaters. Cost was not the only factor. In fact, the commercial astro heaters did not offer a good or at least desirable solution for heating my 12 inch primary. And I could have gone full-on diy with NiChrome wire, but I think the cost of buying NiChrome wire, getting it gauged properly and sized properly, assembled safely, etc. would probably not beat the costs that I incurred.